Improving Turbine Life

Turbines are the backbone of power generation. Repeated exposure to high vibratory stresses and extreme environments leads to stress corrosion cracking (SCC) and fatigue failure in the turbine blades. Replacing damaged blades costs millions of dollars and can take months. The use of welding and identical replacement parts result in 50% of failures reoccurring.

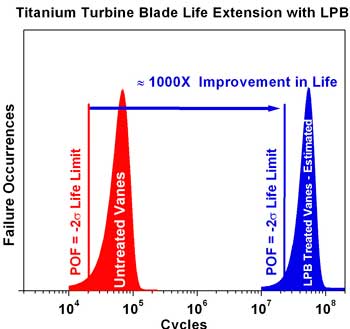

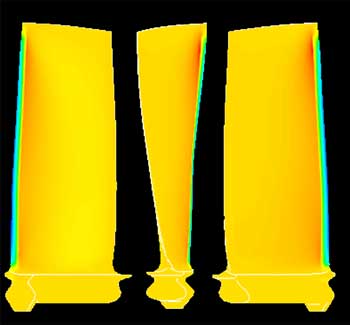

Low Plasticity Burnishing (LPB) applies a deep, stable layer of compression in high stress areas of turbine blades to extend life and reduce costs. LPB arrests damage from the smallest microcracks up to large, easily detectable flaws or corrosion pits. The depth of compression achieved by LPB can restore performance on in-service blades, maximize life on new components, and reduce inspection requirements for turbine operation that is safe, reliable and cost effective.

- Shortens Inspection Times

- Reduces Maintenance and Replacement Costs

- Increases Safety

- Prevents Forced Shut Downs and Outages

- Restore Strength After Weld Repair

Processing can be performed at Lambda’s facilities or a complete turnkey system can be installed in the manufacturing plant or maintenance facility. Operating an automated LPB system does not require extensive training and equipment can be suited to match existing CNC machines or robots. The LPB process only takes a few minutes. LPB processed parts are still 100% original equipment. The life extension afforded by treating the surface makes running OEM components cheaper than buying aftermarket blades. LPB processing costs only a fraction of the cost of replacement blades, providing extended operating life and savings over time.

Read more about how LPB can improve turbine life:

Case Studies of Fatigue Life Improvement Using Low Plasticity Burnishing in Gas Turbine Engine

Miitigation of Fretting Fatigue Damage in Blade and Disk Pressure Faces

For a demonstration of how Low Plasticity Burnishing can increase your turbine life, please contact us by phone at (800) 883-0851 or send us a request email here.