Controlled Plasticity Burnishing

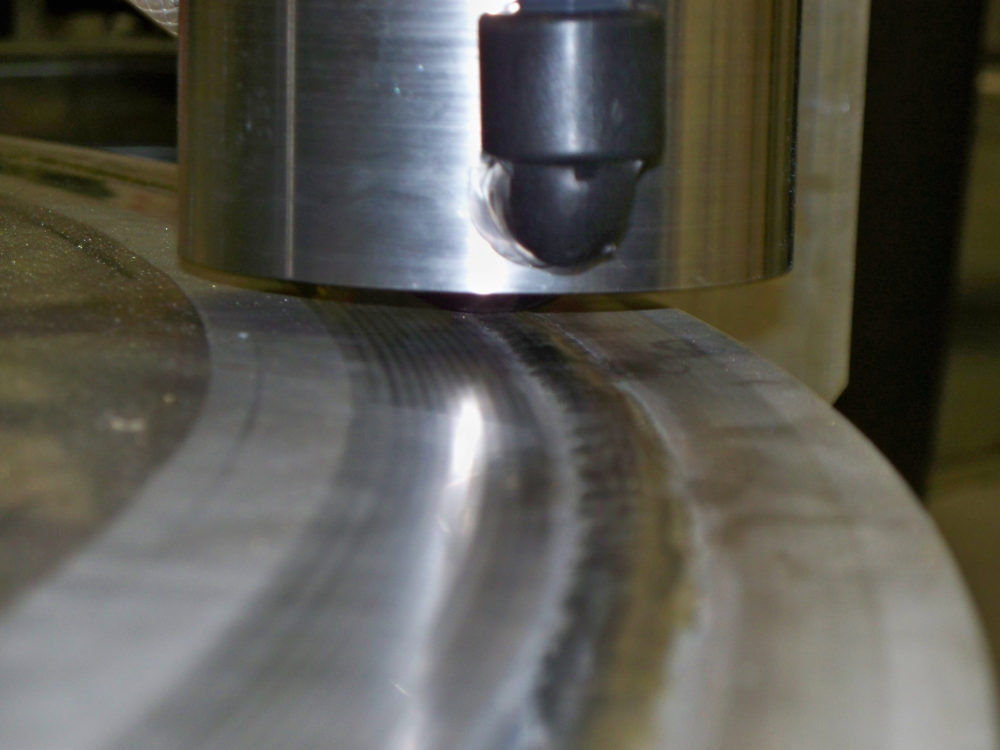

Controlled Plasticity Burnishing (CPB™) is a variation of Lambda Technologies Group’s patented LPB® process. It is specifically designed for applications where low cold work isn’t necessary.

In addition to mitigating damage mechanisms through the application of engineered residual compression to depths exceeding 0.05 inches, Controlled Plasticity Burnishing can also:

- Increase surface hardness

- Reduce surface roughness

- Induce work hardening below the surface

Like LPB, CPB also produces a deep, stable layer of beneficial compressive residual stress into the surface of components. The depth, magnitude and distribution of the compression are designed specifically for each individual component and application.

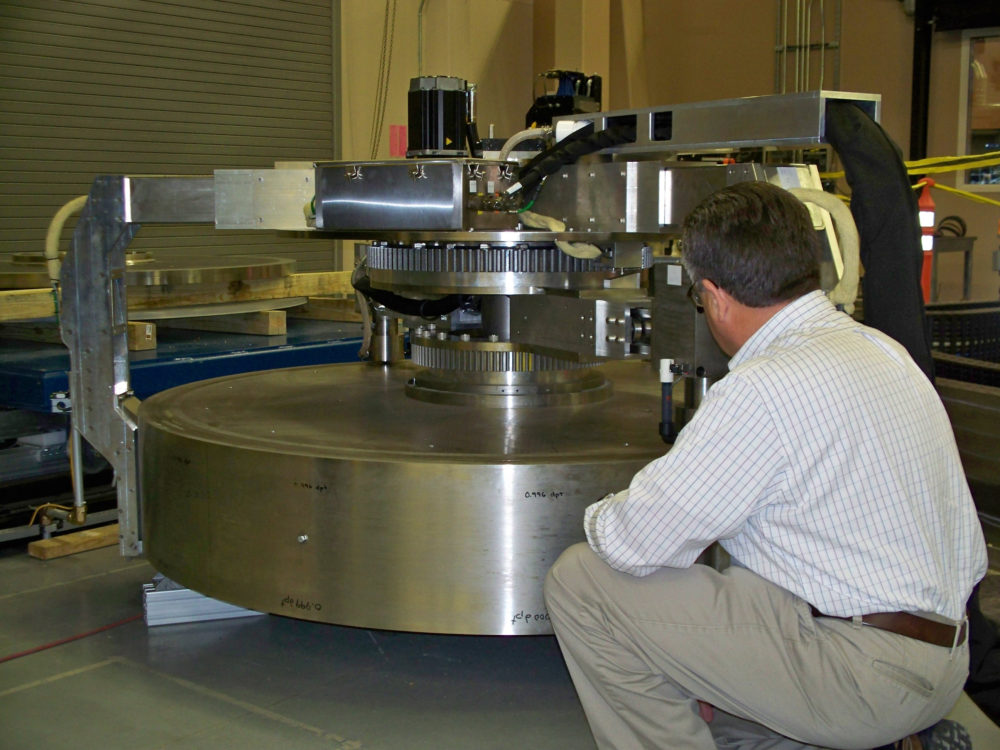

Container at Yucca Mountain

CPB of a nuclear waste container

How is CPB™ different from other surface treatments?

- Quality Control Better than Six Sigma: CPB is 100% closed loop monitored with component tracking, automatic, immediate acceptance testing, and statistical process control

- Accurate & Repeatable: Controlled by CNC or robotics, ensuring a uniform, repeatable production process.

- Turn-Key Production: Easily performed on the shop-room floor, requiring no remote facilities, minimal operator intervention, and allowing fewer chances for human error.

Applications for CPB™ include:

- Improving the mechanical properties of components made through additive manufacturing

- Lowering fatigue crack initiation and crack growth rates through microstructural control

- Controlling corrosion around welds and other vulnerable areas

- Introducing designed hardness and other physical property gradients

- Strengthening the bond of coatings to the substrate

- Eliminating porosity in the surface or coating

Read more about our CPB applications in our case studies or contact us to learn how CPB can improve the performance of your component.