Crystallite/Lattice Parameter Measurement

What is X-ray Diffraction Crystallite Size and Strain Determination?

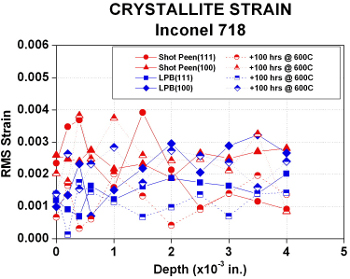

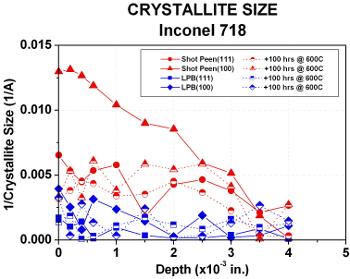

Crystallite size is the effective size of the coherent diffracting domains within a polycrystalline specimen. Microstrain is the degree of distortion present in the crystalline lattice. Both crystallite size and microstrain in the crystal lattice affect the broadening of the X-ray diffraction lines. This line broadening can be used to measure both crystallite size and microstrain.

How is it measured?

Lambda provides the unique capability of determining crystallite size and microstrain by the X-ray diffraction integral breadth method. The integral breadth method involves measuring the line broadening of specific diffraction lines to determine both crystallite size and microstrain. In cases where the microstrain can be assumed negligible, the crystallite size is determined by the Scherrer equation.

Applications:

- Silicon Wafer Semiconductors

- Graphite Fibers

- Coatings and Platings

- Powders

What is Lattice Parameter Measurement?

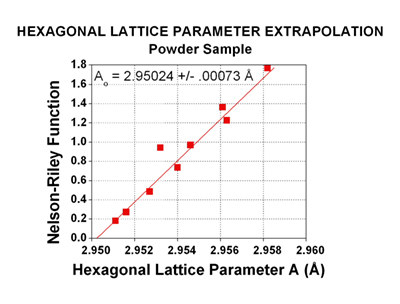

Many applications in material science rely on precise knowledge of lattice parameters. Lattice parameters can be used to determine the composition of a given solution, strain in the crystal lattice, or thermal expansion coefficients. Lattice parameters can be precisely measured using x-ray diffraction methods. Lambda offers the determination of precise lattice parameters for cubic, hexagonal, and tetragonal phases using either powder or solid samples.

How is it measured?

Lattice parameters are calculated from the lattice spacing of any particular set of lattice planes. By measuring the Bragg angle for a set of crystallographic planes, the lattice parameter can be determined. Diffraction data are reduced using Cohen’s Error Function technique, where the unit cell dimension is extrapolated against the Nelson Riley Error Function. Using this method, Lambda provides the most accurate measure of the lattice parameter on your samples.

Applications

- Carbon Disks and Powders

- Alloys

- Films

- Ceramics

How are Lambda’s XRD services superior?

Questions about our testing parameters or techniques?