Surface Integrity

Surface Integrity describes the influence of surface properties and conditions upon material performance.

It’s known that the method of surface finishing and the complex combination of surface roughness, residual stress, cold work, and even phase transformations strongly influence the fatigue and stress corrosion behavior of materials. The influence of surface finishing is most pronounced in high strength alloys, typically chosen for the most critical applications.

How is it Measured?

Lambda provides a comprehensive selection of testing and engineering services for the design of manufacturing processes to ensure optimal residual stress, cold working, and surface finish. Procedures such as grinding, milling, turning, broaching, welding, and heat treatment can be optimized to provide superior component strength. Surface enhancement processes such as shot peening, low plasticity burnishing (LPB®), and laser shocking can be optimized to provide improved fatigue strength, damage tolerance, and stress corrosion cracking resistance.

Our surface integrity assessment testing services are described below.

High Cycle and Low Cycle Fatigue Testing

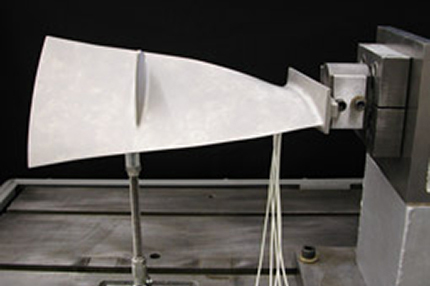

Fatigue testing is required to characterize the influence of residual stress and cold work on fatigue strength. Lambda has both high and low cycle fatigue testing capability specifically developed for measuring the effect of residual stress on fatigue strength and damage tolerance. Fatigue tests can be conducted on full components or feature specimens.

Features of Fatigue Testing:

- High and low cycle fatigue testing for characterization of residual stress influence on fatigue strength and damage tolerance

- Design and manufacture of fatigue test specimens and fixtures

- Custom designed fatigue specimen geometries for measuring the effects of residual compression on fatigue strength

- Up to 50,000 lb load capacity fatigue machines

- Active corrosion fatigue testing

- Elevated temperature testing capabilities

- Continuous compliance monitoring

- Video capture of crack propagation

- Machining of simulated damage

- Rotating Beam Fatigue (R.R. Moore style tester)

Rolling Contact Fatigue Testing

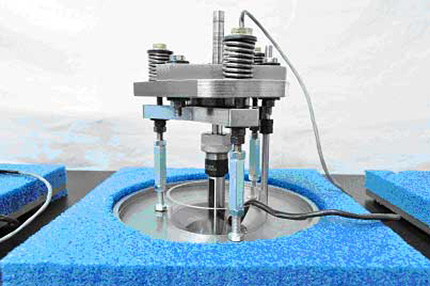

Bearings are used in a significant number of critical mechanical systems. The useful life of these systems is directly related to the fatigue strength of the bearing. Rolling contact fatigue (RCF) is a leading cause of bearing failures. Parameters such as residual stress, retained austenite, surface finish, and lubrication type play a significant role in bearing life.

Lambda provides rolling contact fatigue testing for the study of bearing performance. Using a ball-rod type RCF machine system built by our engineers, Lambda designs and conducts bearing fatigue tests to aid in the optimization of bearing system parameters, material properties, and fatigue performance.

Features of Rolling Contact Fatigue Testing:

- Measurement of residual stress and retained austenite before and after RCF testing to study their effect on fatigue

- Ability to vary contact loads

- Studies of surface roughness effects on bearing life

- Testing of different ball materials or hardness

- Studies of various lubrications

- Weibull probability analysis

Stress Corrosion Cracking (SCC) Testing

Stress corrosion cracking (SCC) is a serious metallurgical problem facing many industries, including nuclear, aerospace, and power generation. A combination of a susceptible material, a corrosive environment, and tensile stress over a threshold limit will result in SCC. Machining, welding, and other fabrication processes can produce high tensile residual stresses and cold working in the surface and near-surface material of critical components providing the driving mechanism for SCC. Surface enhancement processes can be used to mitigate SCC by eliminating the tensile stresses. Lambda provides SCC testing services to measure the effect of machining and surface enhancement methods on SCC mitigation.

Features of Stress Corrosion Cracking (SCC) Testing:

- Numerous test fixtures for simultaneous testing of multiple specimens

- Instrumented load bolts for continuous computer monitoring and recording of load versus exposure time

- Custom corrosive solutions for the simulation of specific environments

- In-house manufacture of test specimens

General Corrosion Testing

Surface finish, cold working, and residual stresses can impact the general corrosion characteristics of components. Lambda provides alternate immersion testing to characterize the influence of a surface finishing or machining process on the general corrosion properties of components.

Features of General Corrosion Testing:

- Alternate immersion tests per ASTM G44

- Large holding rack for multiple sample testing

- Evaluation of corrosion pit size and frequency versus exposure time

- Pre-corrosion of fatigue samples

- Optimization of machining or surface finishing process for minimal corrosion

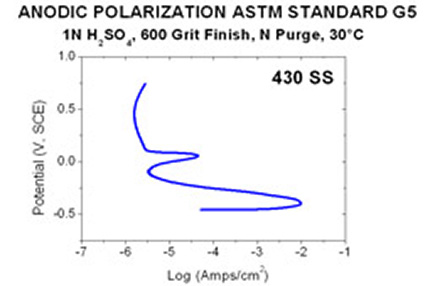

Polarization Testing

Lambda utilizes polarization testing employing a custom electrochemical cell to evaluate the corrosion behavior of materials and surface treatments in a given electrolyte. Polarization testing is a rapid form of corrosion testing yielding results in a matter of minutes or hours. It allows for observation of corrosion behavior over a wide range of oxidizing conditions in a particular environment. This data can then be used to model in-service corrosion response of multiple alloy components.

Features of Polarization Testing:

- Real-time corrosion rate measurement

- Rapid testing and assessment

- Evaluation of surface treatments and machining on corrosion properties

- Results can be used to model corrosion behavior of components and multi-component systems

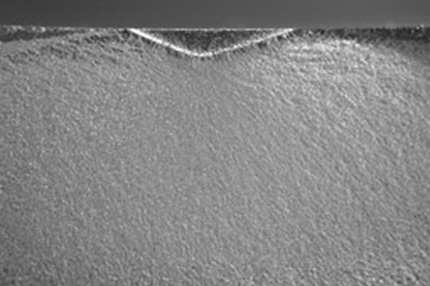

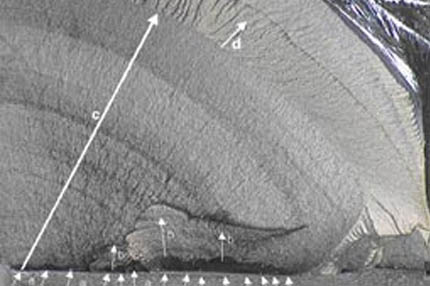

Metallography

Lambda provides metallographic analyses to determine fatigue initiation sites, corrosion damage, and other features relating to component failure. Both optical and scanning electron microscopes are available for an accurate assessment of the failure mode and location.

Features of Metallography:

- SEM and optical microscopes

- Fatigue failure initiation determination

- Fatigue striation counting for approximating applied cyclic stress

- Fretting damage and micro-crack analysis

- Support for process optimization studies

Lifing Analysis

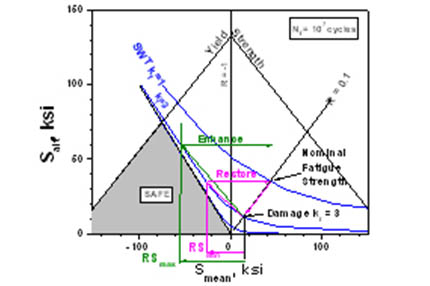

Lifing Analysis is an important, cost-effective testing option prior to engineering. It allows customers to determine what a surface treatment will do for their part theoretically before committing to the time and costs of an engineering effort.

Features of Lifing Analysis:

- Predicts fatigue behavior in the presence of both damage and residual stress

- Provides a design guideline for determining the compressive residual stress magnitude needed to achieve a target damage tolerance

- Allows reduced use of excess material in part design providing significant weight savings and lower production costs

- Enhanced part life and performance reduces maintenance and replacement costs as well as costly downtime

Learn more about Lambda’s proprietary approach to lifing analysis here, as well as linear elastic fracture mechanics (LEFM) to predict fatigue crack growth behavior.

Failure Analysis

Failure analysis is used to determine the cause of a component failure. The goal is to determine the cause quickly and efficiently and provide solutions to improve component strength and life. Lambda uses state-of-the-art equipment and advanced modeling techniques to provide comprehensive failure analysis.

Features of Failure Analysis:

- Establishes the failure mechanisms, calculates the stresses at failure, and provides a complete history of crack growth in a component

- Establishes a chronological account of a component’s service history with loads and cycles

- Accurately assesses stresses at the failure location

- Analyses can be conducted on a replica of the fracture face, eliminating the need to have access to sensitive hardware

Learn more about Lambda’s failure analysis services.

Process Optimization

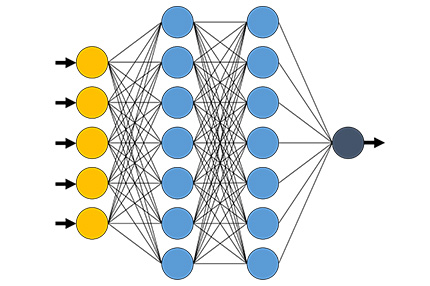

Artificial neural networks and machine learning algorithms are powerful tools for solving complex problems; Lambda applies neural networking techniques to optimize surface treatments.

We have accumulated vast amounts of experience and data from decades of internal studies related to the effects of residual stress on part performance. We have combined this accumulated knowledge and database with the advanced computing power of the latest machine learning and finite element analysis techniques to provide us with a powerful tool for predicting the residual stress and fatigue life improvements achieved from multi-variable processes including surface treatments, machining and heat treatments.

Features of Artificial Neural Network Analysis:

- Leverages an extensive database of residual stress measurements made on a wide range of materials and surface treatments

- Neural network regression analysis produces models for predicting processing results given a complicated set of input relationships

- Permits greater understanding of the influence each individual parameter has on the process output, which allows for the optimization of one or more of those parameters

- Provides a starting point and minimizes the amount of component testing required during a process optimization study

Questions about our testing parameters or techniques?