DIFFRACTION NOTES 5521 FAIR LANE, CINCINNATI, OH 45227 (513) 561-0883 No. 40 Fall 2013

USE OF ENGINEERED COMPRESSIVE RESIDUAL STRESSES TO MITIGATE STRESS CORROSION CRACKING AND CORROSION FATIGUE IN SENSITIZED 5XXX SERIES ALUMINUM ALLOY

A commonly used aluminum alloy in shipbuilding, AA5083-H116 is prone to low temperature sensitization, leading to beta-phase (Mg2Al3) precipitation. The precipitation around the grain boundaries increases the material's susceptibility to stress corrosion cracking (SCC) and corrosion fatigue (CF). Sensitized material is commonly found in heat-affected zones (HAZ) from welding and other heat sources. The United States Navy has issued a directive to solve this problem, as it dramatically affects operation and maintenance (O&M) costs and fleet performance.

It has been shown that minimizing tensile stresses can lower SCC susceptibility and improve CF performance. Furthermore, a means of reliably introducing a deep layer of compressive residual stress in critical heat affected zones can reduce O&M costs by extending the service life of components. Low plasticity burnishing (LPB®) is an advanced surface enhancement process providing a means of introducing compressive residual stresses into metallic components for enhanced CF life, damage tolerance, and SCC performance.

An extensive study was conducted at Lambda Research to evaluate the effects of compressive residual stress on the CF and SCC properties of sensitized and unsensitized AA5083-H116 material.

SPECIMEN MACHINING AND SENSITIZATION

Trapezoidal cross section fatigue samples were machined from AA5083-H116 plate at Lambda's full-service CNC machining facility. These specimens remained in the baseline (as-machined) condition or were LPB processed at Surface Enhancement Technologies (SET) to produce a deep layer of high magnitude compression.

Select groups of LPB specimens and baseline specimens were sensitized at two different temperatures using a computer-controlled oven. The degree to which the specimens were sensitized was quantified by nitric acid mass loss tests (NAMLT) performed in Lambda Research's Corrosion Laboratory per ASTM G67.

SALT WATER EXPOSURE

Prior to fatigue testing, select specimen groups were exposed in Lambda's Corrosion Laboratory to accelerated pitting and general corrosion damage via SCC alternate immersion testing. The active gage region was loaded in tension to 90% of the yield strength in specialized 4-point bend fixtures in an alternate immersion bath of 3.5% weight NaCl solution for 1000 hours per ASTM G44.

CF testing was performed by subjecting the gage region to an environment with 3.5% NaCl solution. Specimens were exposed to this corrosive environment for the duration of the test. Baselines were established by testing specimens from each process group with no corrosion.

RESIDUAL STRESS MEASUREMENT

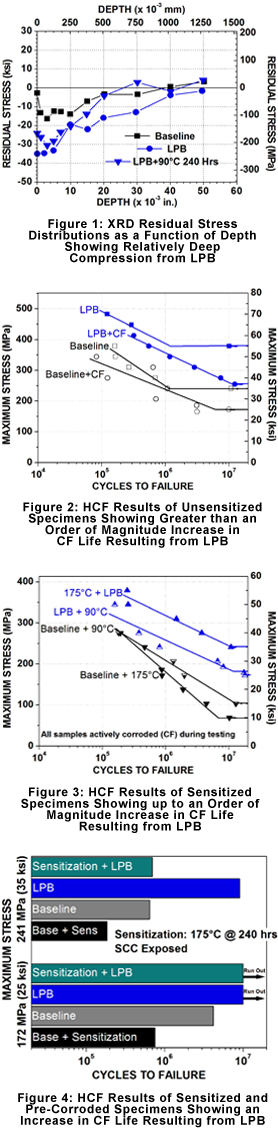

X-ray diffraction (XRD) residual stress measurements were made at Lambda Research's commercial XRD laboratory facility. Measurements were made on test specimens in the baseline, LPB, and LPB + 90oC sensitized conditions. Figure 1 shows the residual stress distributions for these three conditions. The optimized LPB parameters produced compresive stresses to a depth of approximately 0.050 in. with maximum compression, measured near the surface, on the order of -35 ksi. While thermal treatments typically relax residual stress, more than two thirds of the compression induced by the LPB process was preserved after the 90oC sensitization.

HIGH CYCLE FATIGUE TESTING

All tests were performed at room temperature under constant amplitude loading at Lambda Research's Surface Integrity & Process Optimization facility (SIPO). Lambda's high cycle fatigue systems and supporting metallographic analysis capabilities provide a complete set of tools to accurately evaluate the influence of residual stress on fatigue.

The stress vs. life (S-N) results for the fatigue tests are shown in semi-log plot of maximum stress vs. cycles to failure. Figure 2 shows the results for unsensitized material. LPB improved the fatigue strength under most of the conditions tested with an increase of at least 20 ksi over the unprocessed baseline. The LPB + CF conditions tested with an increase of at least 20 ksi over the unprocessed baseline. The LPB + CF condition demonstrated a higher fatigue strength than both the baseline and baseline + CF conditions. LPB provided up to 100x improvement in CF life over baseline specimens.

Data shown in Figure 3 demonstrates the improved CF performance of LPB in sensitized AA5083-H116 material. LPB remained an improvement over the unprocessed condition after sensitization of up to 90oC for 240 hours. When applied after the sensitization process, LPB greatly improved the fatigue life and fatigue strength in material sensitized up to 175oC for 240 hours.

Similar CF performance benefits from LPB were also observed with the pre-corroded SCC specimens detailed in Figure 4. In these tests LPB provided an improvement in CF life over unprocessed material for every tested condition, including those sensitized at the more severe 175oC for 240 hours.

Summary:

- Sensitization caused up to a 60% decrease in fatigue strength of Al5083

- Compressive stresses from LPB reached a depth of 1 0.050 in. (1.27 mm); deeper than any expected corrosion damage

- CF life improved by up to 100x after LPB processing

- 3.5X improvement in CF strength when LPB is applied after sensitization exposure - e.g. as in a repair process of welds or existing structures already exposed to thermal loads

- 70% improvement in CF strength when LPB is applied prior to sensitization exposure - e.g. as in preventive application of new structures that will be exposed to solar energy or high thermal loads

LPB can be applied to pre or post-sensitized AA5083-H116 components to improve corrosion fatigue life and SCC performance, ultimately reducing operation and maintenance costs of naval ship superstructures.

ANNOUNCEMENTS

Lambda provides hole-drilling residual stress measurement services per ASTM E837-08. We have developed specialized tooling to allow hole-drill measurements to be made on test samples with minimal access, such as on the inside diameter of components. Please contact Doug Hornbach or Tom Lachtrupp for more information.

Lambda provides rolling contact fatigue (RCF) testing for the study of bearing performance. Using a ball-rod type fatigue testing device, we can conduct tests to aid in the optimization of bearing system parameters, material properties, and fatigue performance. We can measure residual stress and austenite before and during testing to study their effect on fatigue. Please contact Perry Mason or Kyle Brandenburg for more information.

POWER-GEN - November 12-14, 2013 - Orange County Convention Center - Orlando, FL

Doug Hornbach will be presenting a paper on Wednesday, November 13, in Session 12C titled, "Use of Engineered Compressive Residual Stresses to Mitigate Stress Corrosion Cracking and Corrosion Fatigue."

Lambda's Kyle Brandenburg presented a paper titled, "Use of Engineered Compressive Residual Stresses to Mitigate Stress Corrosion Cracking and Corrosion Fatigue in Sensitized 5XXX Series Aluminum Alloys," at the 2013 DOD Corrosion Conference. Download the paper here.

For more information about our testing capabilities, accreditations, or other publications,

visit our website at www.lambdatechs.com.